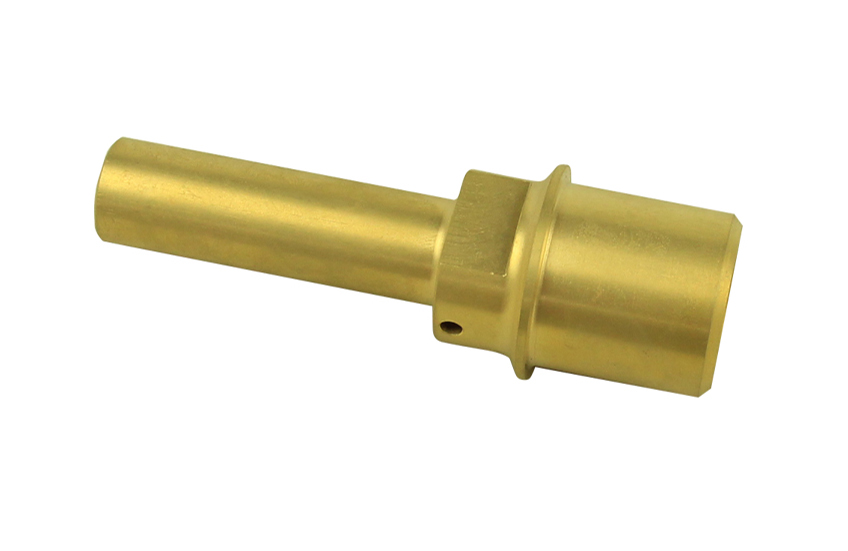

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape.

Some of the reasons for selecting CNC turning include:

CNC turning is faster in comparison to manual turning.

Products can be mass produced without any deviation.

Constant supervision is not necessary to perform a task, which helps in improving work efficiency as well as productivity.

There are different types of CNC turning processes, let us look at them here:

Hard Turning: This type of turning is used for heat treated materials which have Rockwell C hardness of more than 45. Injection pump components, gears, and hydraulic components are some examples where this type of hard turning process is commonly used.

Tapered Turning: Here hydraulic copy attachment, form tool, or a CNC lathe is used to perform such tapered turning. It is considered a suitable method in case work is to be performed on shallow tapers.

Spherical Generation: In case of spherical generation any specific form is generated using a fixed axis of revolution.

Facing: In this process cutting tool faces rotating work piece at right angle. Normally, during production of any work piece, it is the first or the last operation that is undertaken.

Parting: This method is used for separating smaller parts out of a larger block.

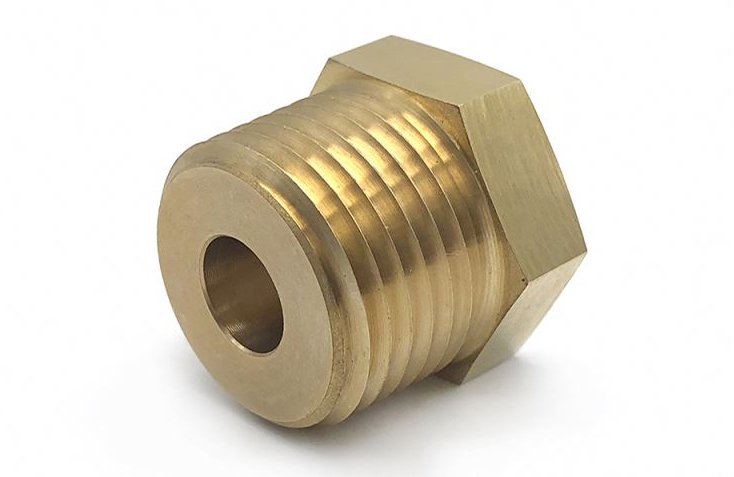

Grooving: It involves cutting grooves of specific depth on external as well as internal surface of the material.

Knurling: This process can be utilized for creating hand grip on surface of the material.

Reaming: Reaming is used for removing very small amount of material out of a hole that has already been drilled. The aim here is to create internal holes with accurate diameters.

Aluminum: 5052, 5083, 6061-T6, 6063, 6082, 7075-T6, A380

Stainless steel: SUS201, SUS303, SUS304, SUS316l, 420, 430,440C

Carbon Steel: 1018, 1020, 1045, A36, Q235, Q345B

Alloy steel: 4130, 4140, 4150, 4340, 6150

Tightest tolerance: ±.0004inch (0.01 mm) Tighter tolerances are examined on a case by case basis with your technical drawings.

General tolerances are in line with standard of DIN ISO 2768-mK.

Our project managers will consult with you on every part of your project and will seek to provide the highest degree of precision possible.

Part size / Dimension | Tolerance | Angularity |

|

< 12’’ (30 mm) |

± .005’’ (0.125 mm) |

± 0.5° |

< 24’’ (60 mm) | ± .010’’ (0.250 mm) | ± 1.0° |

< 36’’ (90 mm) | ± 1/64’’ (0.400 mm) | ± 1.0° |

Surface

Choose the right surface to your CNC machining parts

Picturesof finished samples

As Machined

Ra 3.2~Ra 12.5 µm.

Micro processing traces to Micro machining tool marks.

No further surface treatment after the part is machined. If the products don’t need special surface protection or decoration, it can be fine and cost effective to choose none surface finishing requirement.

Smoothed surface

Minor direction of processing lines

We keep lower feed rate and high speeding spindle to control the surface

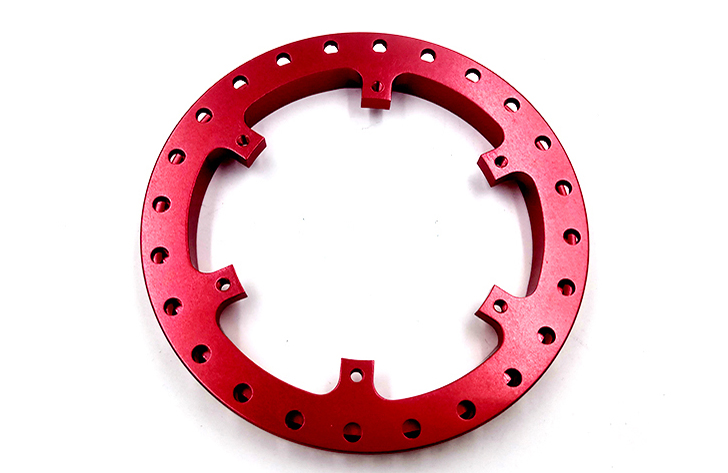

Anodized surface

Anodizing is an electro chemical process that converts the aluminum into a decorative, durable, corrosion-resistant, anodic oxide finish. Available in a variety of colors, like Blue, red, black, etc.

Powder Coating

Powder coat paints with texture (Sandtex Polyester and Textured Polyester) will cover tool marks with no additional finishing operation. Available in a wide range of colors.

Electropolished finish

Electropolishing is an electrochemical process used to polish, passivate and deburring metal parts. It is useful to reduce surface roughness.

Black oxide

Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection.

Plated surface

Plating can serve as a layer of protection. It is applied to metal objects when three is an increased opportunity for corrosion to occur. Including (Yellow, Blue, White, Color) Zinc Plated, Chrome Plated, Nickel Plated.

Blasting

Sand blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to removing all tool marks. We can provide matte or satin surface finish on a machined part. Mainly used for aesthetic purposes.